Magnus

Well-known member

This might not be interesting for people in the US but...

...a few weeks ago ECI (European Color Inititive) together with Fogra and GMG released a new icc-profile based on Fogra 53 - the eciCMYK.icc.

http://www.eci.org/en/colourstandards/workingcolorspaces

https://www.fogra.org/en/fogra-rese...hange-space-fogra53-and-ecicmyk-released.html

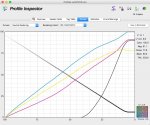

The idea seems to be 'One CMYK-profile to rule them all' or as ECI and Fogra calls it CMYK Exchange Colorspace. The wide gamut of the new profile covers all common CMYK-profiles and ISO-standards and got a white point of L 96,5 a 1 b -3 and a max black point that is about L 5 a 0 b 2.

I think that this might be very good for designers and big companies who buys a lot of print with multible print techniques. In theory they can deliver one single file for multiple purpose (and maybe even approve one single hard proof). The conversion to the destination printing condition would be preformed in the RIP (or in a prior step like preflight), but the designer doesn't need to care... If I understand the idea properly.

What is your input regarding this? Ups and downs? Do you think this will be adopted as a 'de facto standard' in the future? Or will it fade out like the eciRGB project?

Keen to hear what you guys think!

Best regards,

Magnus

...a few weeks ago ECI (European Color Inititive) together with Fogra and GMG released a new icc-profile based on Fogra 53 - the eciCMYK.icc.

http://www.eci.org/en/colourstandards/workingcolorspaces

https://www.fogra.org/en/fogra-rese...hange-space-fogra53-and-ecicmyk-released.html

The idea seems to be 'One CMYK-profile to rule them all' or as ECI and Fogra calls it CMYK Exchange Colorspace. The wide gamut of the new profile covers all common CMYK-profiles and ISO-standards and got a white point of L 96,5 a 1 b -3 and a max black point that is about L 5 a 0 b 2.

I think that this might be very good for designers and big companies who buys a lot of print with multible print techniques. In theory they can deliver one single file for multiple purpose (and maybe even approve one single hard proof). The conversion to the destination printing condition would be preformed in the RIP (or in a prior step like preflight), but the designer doesn't need to care... If I understand the idea properly.

What is your input regarding this? Ups and downs? Do you think this will be adopted as a 'de facto standard' in the future? Or will it fade out like the eciRGB project?

Keen to hear what you guys think!

Best regards,

Magnus