YourCastle

Well-known member

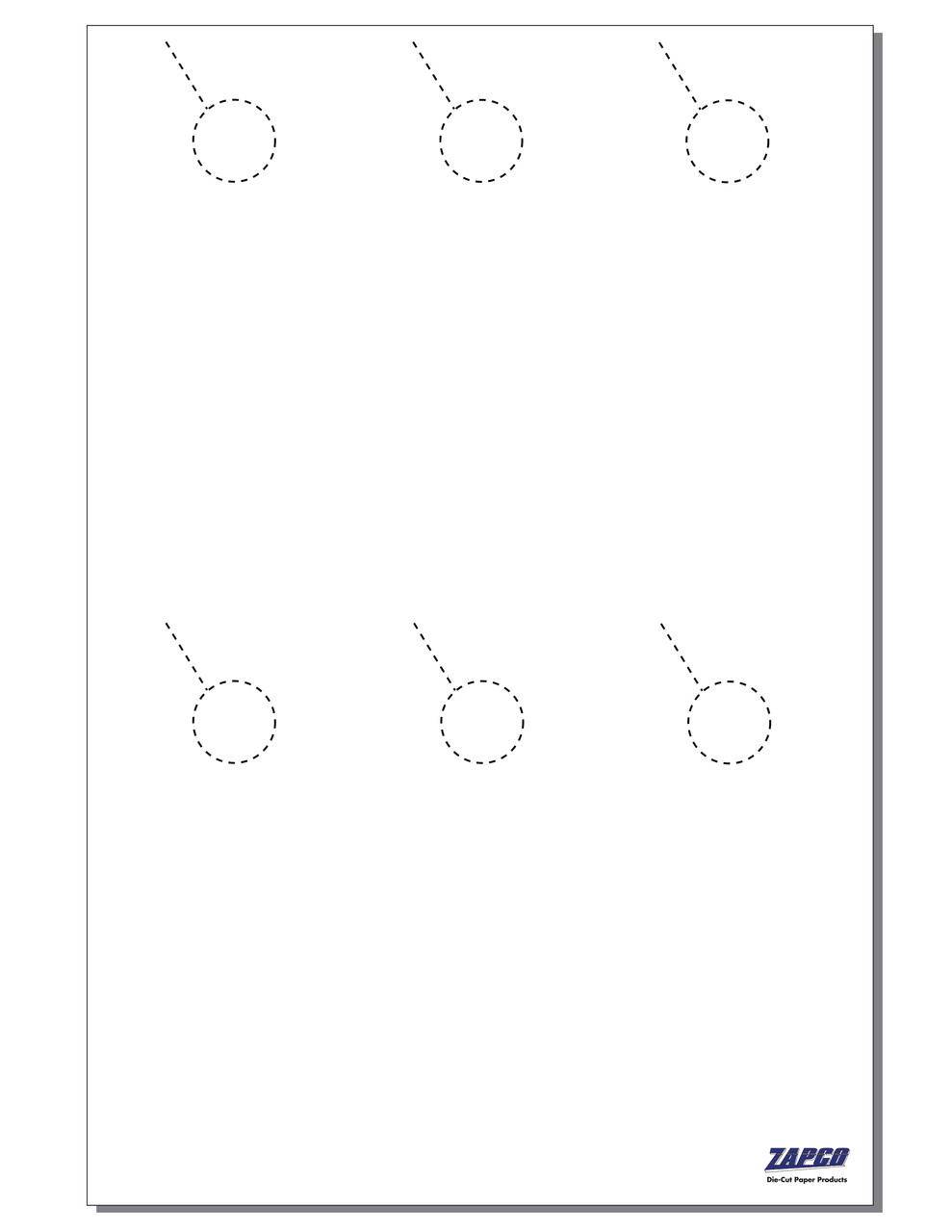

My company has been using door hanger paper that's 6up, 12x18, and fully perforated. Since i have a duplo, I'm hoping to find a vendor that sells only the slit and hole perforated.

The lead edge perforated causes my duplo issues. Since i need to order more, i thought I'd ask.

I'll explore editing my duplo program to trim more of the lead, but would just prefer the partial perf, if it exists.On

Thanks!

The lead edge perforated causes my duplo issues. Since i need to order more, i thought I'd ask.

I'll explore editing my duplo program to trim more of the lead, but would just prefer the partial perf, if it exists.On

Thanks!