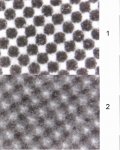

#1 and #2 are 45% bar on jobs run on same

press, K unit within a few days of each other.

Same stock, same side of stock, same bar,

same CTP, same plate brand.

We are having a disagreement on the cause

of this and I've been asked to get the opinions

of professionals without my opinion so as to not

lead or sway the answers.

Any input would be greatly appreciated.

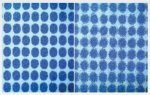

press, K unit within a few days of each other.

Same stock, same side of stock, same bar,

same CTP, same plate brand.

We are having a disagreement on the cause

of this and I've been asked to get the opinions

of professionals without my opinion so as to not

lead or sway the answers.

Any input would be greatly appreciated.