cDirect

Active member

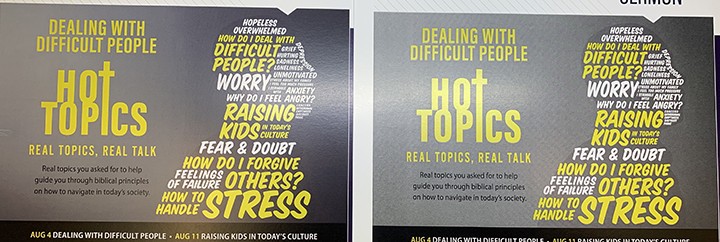

So my 9110 has always had poor gray application or printing good gray gradients. It has been an issue with Ricoh's machines since time immemorial.....I had a job that had a 5x7 part of gray gradient and I was normally converting that part to RGB in PitStop or if i had the native file making it RGB. You roll the dice when you do that because you can get some serious green "gray". I was not looking good even with a new profile so I was toying around with settings and I came across a setting in the Color section in the Color Input that reads "Print CMYK gray using black only". This is normally turned on by default but when I turned it off.....BOOM. Started getting a workable gray gradient and a slight amount of magenta. I simply knocked out some magenta using the Image Preview feature and my gray became a very sellable gray gradient.

Left image: Print CMYK gray using black only" turned off

Right image: Print CMYK gray using black only" turned on for "Text/Graphic/Images" per default.

Not sure if I am simply an idiot for not ever noticing this but it made a lot of sense once i understood what it was doing. Glad I found it and hope it helps someone else because every time I asked Ricoh they always admitted that gray is always an "issue".

Left image: Print CMYK gray using black only" turned off

Right image: Print CMYK gray using black only" turned on for "Text/Graphic/Images" per default.

Not sure if I am simply an idiot for not ever noticing this but it made a lot of sense once i understood what it was doing. Glad I found it and hope it helps someone else because every time I asked Ricoh they always admitted that gray is always an "issue".