Alith7

Well-known member

I have a question for you guys.

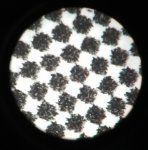

Why would a spot color not be able to hold open a 50% screen?

We have tried at 175 lpi and 200 lpi. Both plug up complete (looks like 100% with a waffle pattern).

Plates are fine, I even tweaked the file to open it up to a 40% screen and they still can't keep it open?

Printing on 100# Gloss Cover, PMS 1505.

I would think it's something wrong with the press or operator error or something, but they keep insisting that the file is bad. I don't see how this could be.

Any input would be a help! I managed to fudge the file enough for the customer to be happy so we could runt he job, but i'd still like to figure out what the %)#($ is going on.

Thank you!

Why would a spot color not be able to hold open a 50% screen?

We have tried at 175 lpi and 200 lpi. Both plug up complete (looks like 100% with a waffle pattern).

Plates are fine, I even tweaked the file to open it up to a 40% screen and they still can't keep it open?

Printing on 100# Gloss Cover, PMS 1505.

I would think it's something wrong with the press or operator error or something, but they keep insisting that the file is bad. I don't see how this could be.

Any input would be a help! I managed to fudge the file enough for the customer to be happy so we could runt he job, but i'd still like to figure out what the %)#($ is going on.

Thank you!