Freeman A.Gain

Well-known member

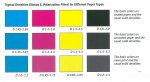

Wow, and our bosses wonder why we sometimes chase colour to match previously printed jobs or supplied samples! Everyone has there own set of "standard" densities. We also have our standards as well;

For coated stocks

C- 1.45

M- 1.35

Y- 0.90

K- 1.65

For uncoated

C- 1.25

M- 1.15

Y- 0.85

K- 1.45

Now having said this, we print with Hybrid inks were the cyan has more of a mag. hue to it, thus the lower values in magenta. We can run a stronger colour on uncoated stocks because no fear of set off.

Its good to see all of the different opinions though.

For coated stocks

C- 1.45

M- 1.35

Y- 0.90

K- 1.65

For uncoated

C- 1.25

M- 1.15

Y- 0.85

K- 1.45

Now having said this, we print with Hybrid inks were the cyan has more of a mag. hue to it, thus the lower values in magenta. We can run a stronger colour on uncoated stocks because no fear of set off.

Its good to see all of the different opinions though.