Gordo,

you had been talking about experience in this thread, would you really recommend this as a method of printing standard colors with increased density in order to achieve a higher gamut than normal?

For my part, I would then always work with other methods (Anniva colors, FM ...), because I would have my doubts that, depending on the printed image, it would not create an unnecessary risk of discarding (traces of color on the back of the sheet or "glueing") if it is printed with significantly more density.

Not to mention that percentage ranges above 95% in the file (at the latest (!) from here on, everything mutate into a full-tone area ...) can not be “easily” reconstructed with a curve correction. Yes, in the midtones you can still win back the neccesary tone-value for a good drawing with a corresponding curve correction, but in the depths above 95% you can at least no longer speak of a "curve" and it seems really difficult for me to do it in a RIP ... !?

I already said, that today, when setting up a printing condition, the primary focus is on the target color locations of the solids in order to determine the ideal (= "normal") density for printing with standard colors.

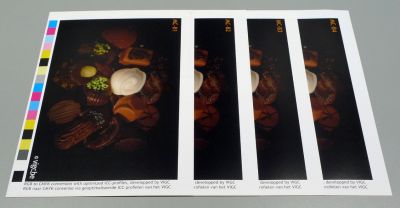

Surprisingly, the result is correct with the corresponding formula …

(Density Solid (DV) minus Density Tone-Value (D 75%) divided through Density Solid (DV) is Contrast in percent (KV), see also here: https: // de. wikipedia.org/wiki/Druckkontrast)

…checked in my experience with FOGRA39 very well, that means, you print with the “standard” density really the highest contrast / most tonal value differences.

You only have to ask yourself once how such a printing condition, the corresponding profile, comes about. The target color locations/the Lab-values for the solids do not fall from the sky. In my humble opinion, an evaluation of the best / highest print contrast is still a helpful method in the age of CTP to determine the target color locations of the solid colors. However, it is hardly needed anymore, because there are already enough characterization data for standard printing conditions and standard inks.

A direct connection with the film exposure era and this evaluation criterion therefore does not open up to me. I think, that this method was just more widespread in earlier times, because standard profiles (at that time still/already “best” FOGRA27 and 29) like the whole colormanagement were just gradually entering the industry - at the same time like CTP.

Best

Ulrich