Dario

Well-known member

Hi all!

I have a customer who gives me press proofs where there are, for each ink, 3 patches: 25-40-80%.

Obviously, if I print the same patches I have to get the exact measurements that I read on his prints (it's the only way).

... now ... I'm confused ...

1) I print the first test without any TVI curve,

2) then I measure the 3 patches,

...and then what?

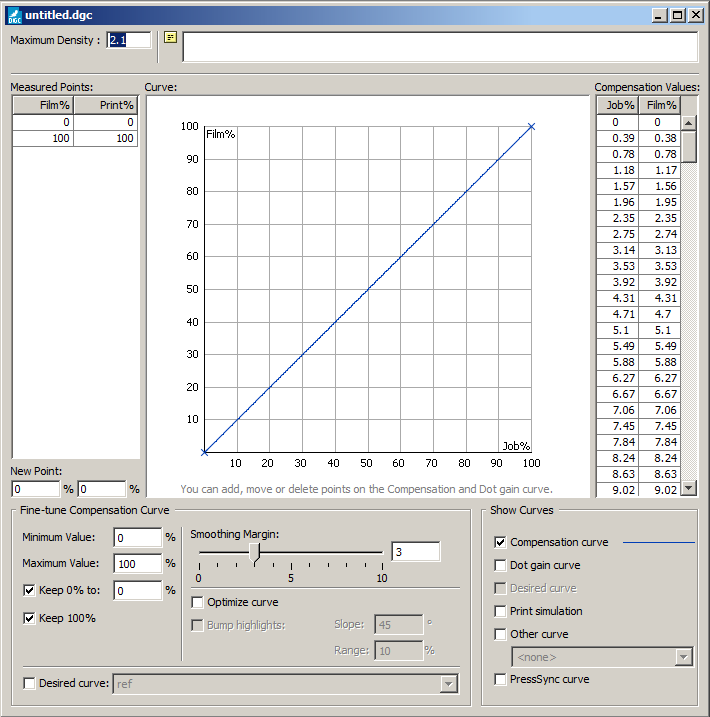

I no longer remember how I should use the data from the different readings to create a TVI curve in my software!

For example:

If I measure the 40% patch and read the same value on his and my printout, then I know the curve is already okay.

But if I read 35% on his patch and 45% on mine, how should I use that data in my program?

Excuse me, but I'm really lost, and I could use some help because I only get to do this every 2 or 3 years!

I have a customer who gives me press proofs where there are, for each ink, 3 patches: 25-40-80%.

Obviously, if I print the same patches I have to get the exact measurements that I read on his prints (it's the only way).

... now ... I'm confused ...

1) I print the first test without any TVI curve,

2) then I measure the 3 patches,

...and then what?

I no longer remember how I should use the data from the different readings to create a TVI curve in my software!

For example:

If I measure the 40% patch and read the same value on his and my printout, then I know the curve is already okay.

But if I read 35% on his patch and 45% on mine, how should I use that data in my program?

Excuse me, but I'm really lost, and I could use some help because I only get to do this every 2 or 3 years!