Bill W

Well-known member

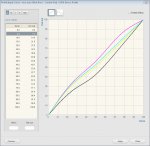

We are running a poly substrate on a flexo press. Raw measurement data analyzed in ColorAnt indicates gain at 2% (1.96% in report) to be 22 - 24%. Press target was IT8.7-4.

After I make a profile, using iProfiler, I check the gain at 2% in ColorThink and it indicates it is around 7%.

When I apply the profile to an IT8.7-4 reference file in ColorThink and then check saved data in ColorAnt it also shows a gain of around 7%.

Using this profile in CGS grossly misrepresents my highlight areas until I built a radical highlight gain curve in CGS.

Help me in understanding why my profile does not match real press TVI.

-Bill-

After I make a profile, using iProfiler, I check the gain at 2% in ColorThink and it indicates it is around 7%.

When I apply the profile to an IT8.7-4 reference file in ColorThink and then check saved data in ColorAnt it also shows a gain of around 7%.

Using this profile in CGS grossly misrepresents my highlight areas until I built a radical highlight gain curve in CGS.

Help me in understanding why my profile does not match real press TVI.

-Bill-