You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

18,000 per hour press speeds .

- Thread starter markprint

- Start date

gordo

Well-known member

Press manufacturers claim that new presses can run 18,000/hr, but is anyone doing it consistently after a few year of these high speeds?

If they're new presses...who would have had a few years of experience with them?

In any case, if they ran at that speed, the average job run time would be about 10 minutes. Most shops would close for the day by 10 am. LOL

Alois Senefelder

Well-known member

Hello markprint,

These days the criterion should be - how fast is the: Downtime/ Makeready too the first Saleable Sheet.

Regards, Alois

These days the criterion should be - how fast is the: Downtime/ Makeready too the first Saleable Sheet.

Regards, Alois

Cornishpastythighs

Well-known member

Packaging printers routinely run long runs at those speeds on cardboard. With a robust maintenance schedule the press will last for many years, that's how they were designed.

I've worked on a pair of Heidelberg XL106 presses in the folding carton industry running stock from .012" to .028" both long and short grain. Generally, the press can run 18000 just fine. Some times slower speeds are better for handling curly boards. And I'll run slower on small orders because I want time to control the process. A thousand sheet order will take a little over 3 minutes at full speed. We've had our first press for 3 years now.

Alois Senefelder

Well-known member

Hello bradcarol,

Don't be silly ....... have you tried feeding 30gsm Airmail Paper at 18,000 IPH

Regards, Alois

Don't be silly ....... have you tried feeding 30gsm Airmail Paper at 18,000 IPH

Regards, Alois

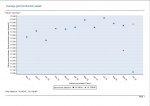

We run 2 Heidelberg XL 106 presses, a 4 color + coater and a 4/4 LED UV with CutStar. The 8 color is 45 days old and has 5.5 million impressions on it, running 3 shifts 5 days a week. The 4 color is 3 years old and has 138 million impressions on it.

Our average run length is under 3,000 sheets. 98% of our impressions are text weight, with 70% of our paper purchases being 70# gloss coated.

We average 3.8 minutes per makeready with an average run speed greater than 17,500 sheets per hour under impression and put 16,250 sheets on the floor every hour.

As for running slower on small orders, that is a mindset tied to older technology. The XL class presses are designed to run at speed and it's easier to control ink/water balance at speed than running slower.

Our average run length is under 3,000 sheets. 98% of our impressions are text weight, with 70% of our paper purchases being 70# gloss coated.

We average 3.8 minutes per makeready with an average run speed greater than 17,500 sheets per hour under impression and put 16,250 sheets on the floor every hour.

As for running slower on small orders, that is a mindset tied to older technology. The XL class presses are designed to run at speed and it's easier to control ink/water balance at speed than running slower.

Attachments

PricelineNegotiator

Well-known member

We run 2 Heidelberg XL 106 presses, a 4 color + coater and a 4/4 LED UV with CutStar. The 8 color is 45 days old and has 5.5 million impressions on it, running 3 shifts 5 days a week. The 4 color is 3 years old and has 138 million impressions on it.

Our average run length is under 3,000 sheets. 98% of our impressions are text weight, with 70% of our paper purchases being 70# gloss coated.

We average 3.8 minutes per makeready with an average run speed greater than 17,500 sheets per hour under impression and put 16,250 sheets on the floor every hour.

As for running slower on small orders, that is a mindset tied to older technology. The XL class presses are designed to run at speed and it's easier to control ink/water balance at speed than running slower.

Best post I've seen on this forum in a few months. Concise.

No doubt those numbers are impressive, but if your run lengths truly average around 3000 sheets, then with 3.8 minute make-readies, you could not produce more than approximately 4 of them per hour.

That equates to roughly somewhere between 12,000 and 13000 saleable sheets on the floor, every hour. Still very impressive.

The 16,250 sheets per hour on the floor is for running time.

In 2017 we produced 58 million impressions on our 4 color press. When you divide 58,000,000 sheets by 6,000 hours (roughly 3 shifts) the result is 9,667 sheets per manned hour on the floor. When you start to factor in planned downtime for maintenance, breaks/meals etc. the sheets per operational hour increase.

The point of my original posting was that these presses (at least the Heidelberg XL presses we run) do indeed run at 18,000 sheets per hour, even on light weight paper and short runs.

We run 2 Heidelberg XL 106 presses, a 4 color + coater and a 4/4 LED UV with CutStar. The 8 color is 45 days old and has 5.5 million impressions on it, running 3 shifts 5 days a week. The 4 color is 3 years old and has 138 million impressions on it.

Our average run length is under 3,000 sheets. 98% of our impressions are text weight, with 70% of our paper purchases being 70# gloss coated.

We average 3.8 minutes per makeready with an average run speed greater than 17,500 sheets per hour under impression and put 16,250 sheets on the floor every hour.

As for running slower on small orders, that is a mindset tied to older technology. The XL class presses are designed to run at speed and it's easier to control ink/water balance at speed than running slower.

Kheslin - Are you running magazine work?

Similar threads

- Replies

- 0

- Views

- 1100

- Replies

- 0

- Views

- 1517

- Replies

- 0

- Views

- 423

- Replies

- 2

- Views

- 632

PressWise

|

A 30-day Fix for Managed Chaos

As any print professional knows, printing can be managed chaos. Software that solves multiple problems and provides measurable and monetizable value has a direct impact on the bottom-line. “We reduced order entry costs by about 40%.” Significant savings in a shop that turns about 500 jobs a month. Learn how……. |