Cornishpastythighs

Well-known member

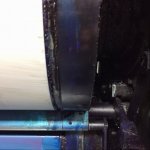

Do you see this issue more at the leading edge or trailing edge of your plate/blanket. I only ask because in certain extreme cases I have seen dot differences caused by the amount of spray glue used to stick packing together, if you glue your press packings together and then glue them to the cylinder you can create some thickness difference. Only minor I know but worth looking into.

Cheers

Cheers