hkellogg

Well-known member

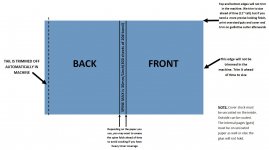

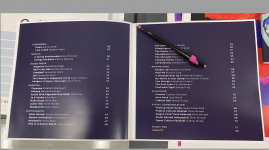

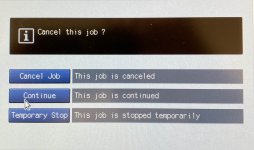

Does anyone have experience with the PB 503 perfect binding unit available on the Konica Minolta AccurioPress and BizHub? It seems that it is a bit finicky when it comes to the size of a pre-printed covers and the main pages of the document. We were able to bind a document but we can't seem to duplicate the process. Anyone familiar with this unit?

Thanks

Hans

Thanks

Hans