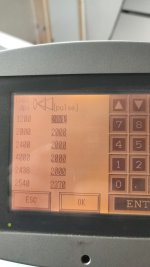

I recently had a technician change some diodes on a heidelberg topsetter. Now I am getting these lines on the black plate.

I cant be sure that we didnt change anything on the RIP these past months as we have been troubleshooting other problems... but we havent had these lines before.

The technician is saying that these lines can only be my RIP.

Anybody has an idea what the problem is?

I cant be sure that we didnt change anything on the RIP these past months as we have been troubleshooting other problems... but we havent had these lines before.

The technician is saying that these lines can only be my RIP.

Anybody has an idea what the problem is?