easiprint

Well-known member

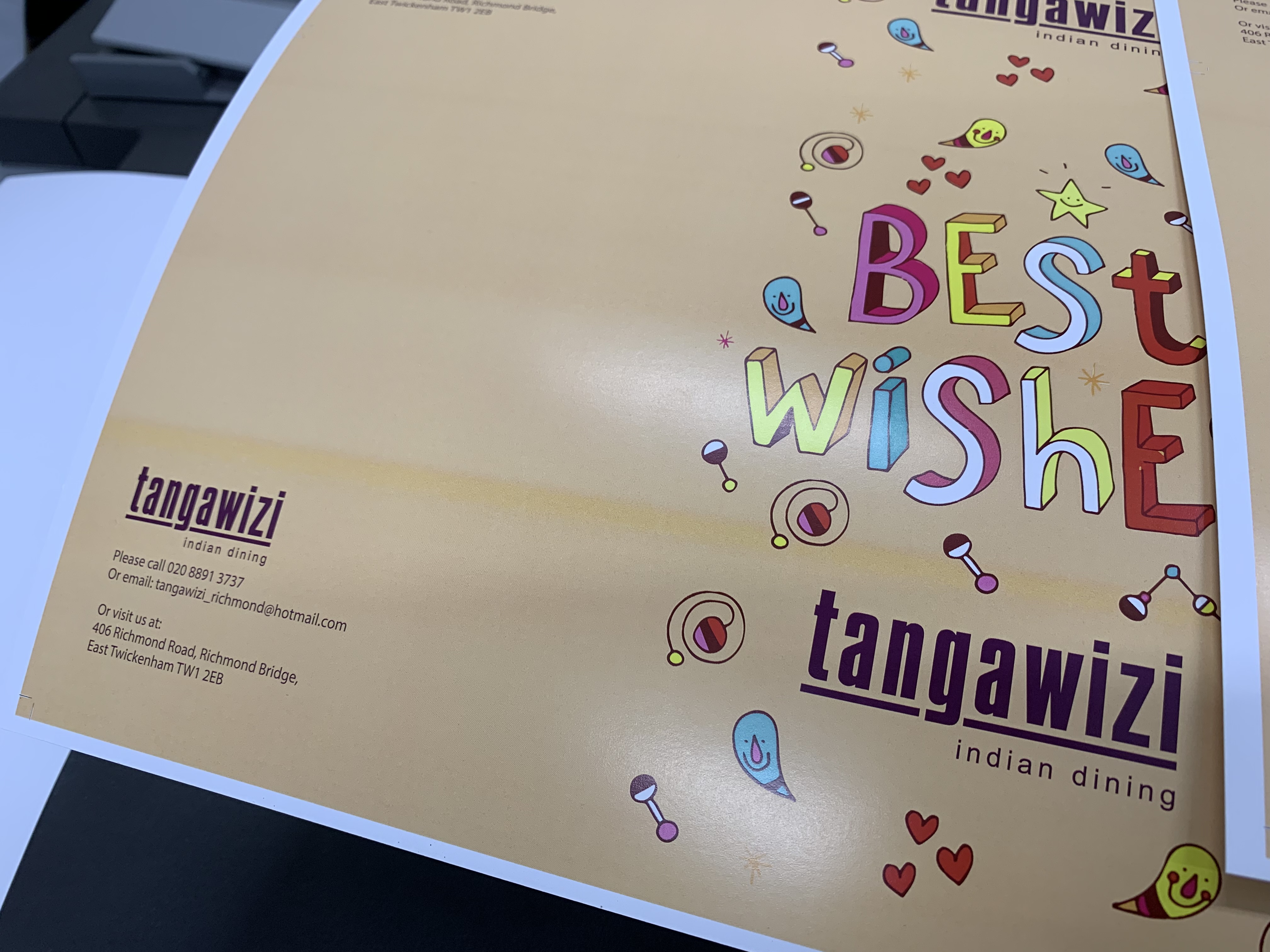

Having an issue on my Ricoh C5100 and C5200 presses with banding on the trailing half of the sheet (see photo!). I've been running these presses for about 4 years now, and never had an issue this bad. With any pastel shades, I get this banding, sometimes one, sometimes two on the end of the sheet. I've called my engineer who says it's jitter due to using 300gsm and 350gsm board and is a problem with all digital presses from all manufacturers. I get if I was pushing above spec, but this machine is rated to 360gsm, so I would expect 300/350gsm to be fine. I'm sure this is a new problem, as I've not noticed it over the past four years, but my engineer says it's a common problem and would have always been there. Anyone else have this issue on boards on Ricoh or any toner press?