Recently switched sources for our 100# gloss text.

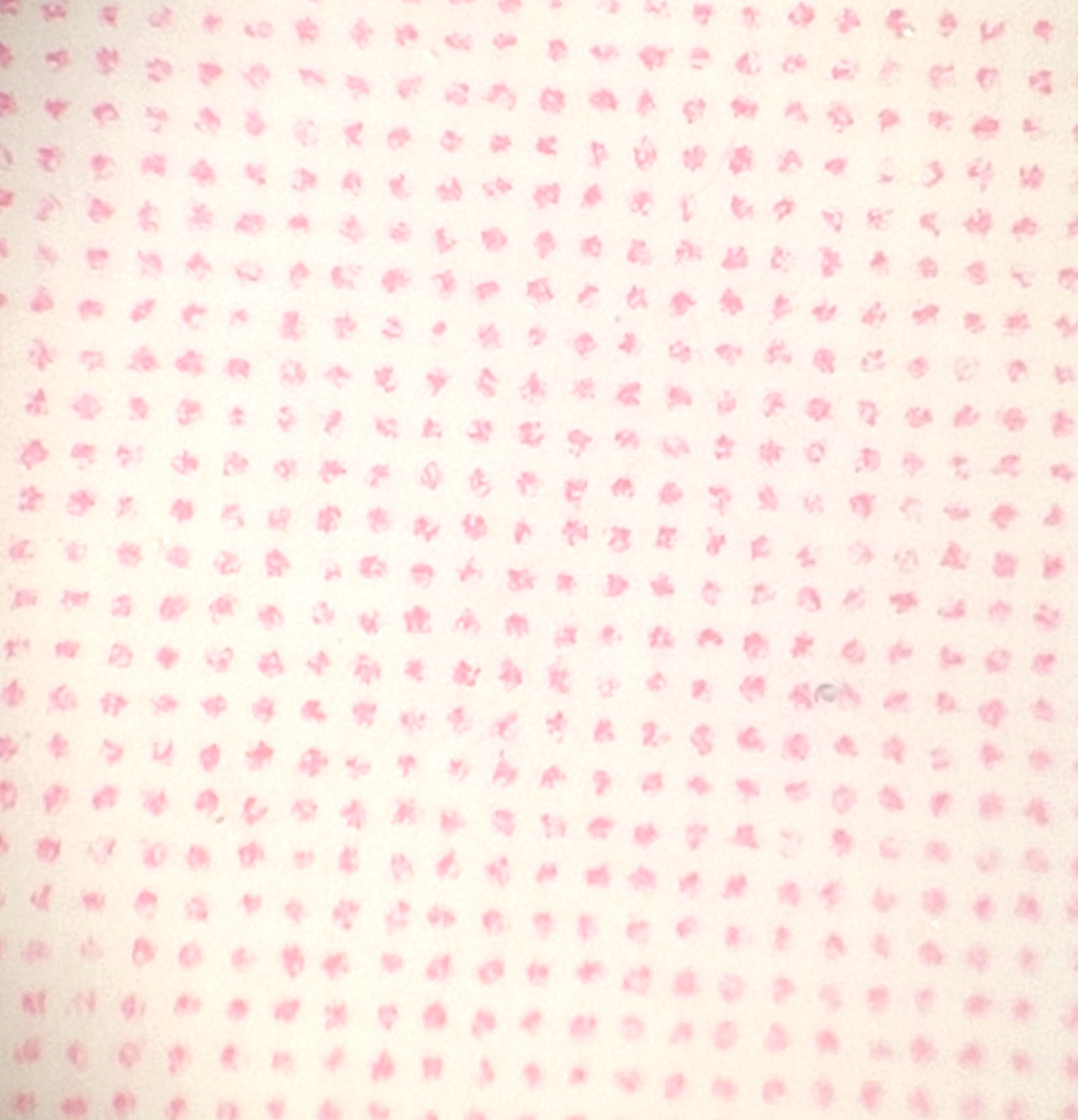

The new paper does not print well as well as the previous paper. We get what I call "Splody-dots".

Unfortunately, it took awhile before we noticed this when we printed some very light screens and was extremely difficult to control the results. We ultimately decided to sharpen the curves in the hi-lites to get the results for which we were calibrated.

See attached jpegs.

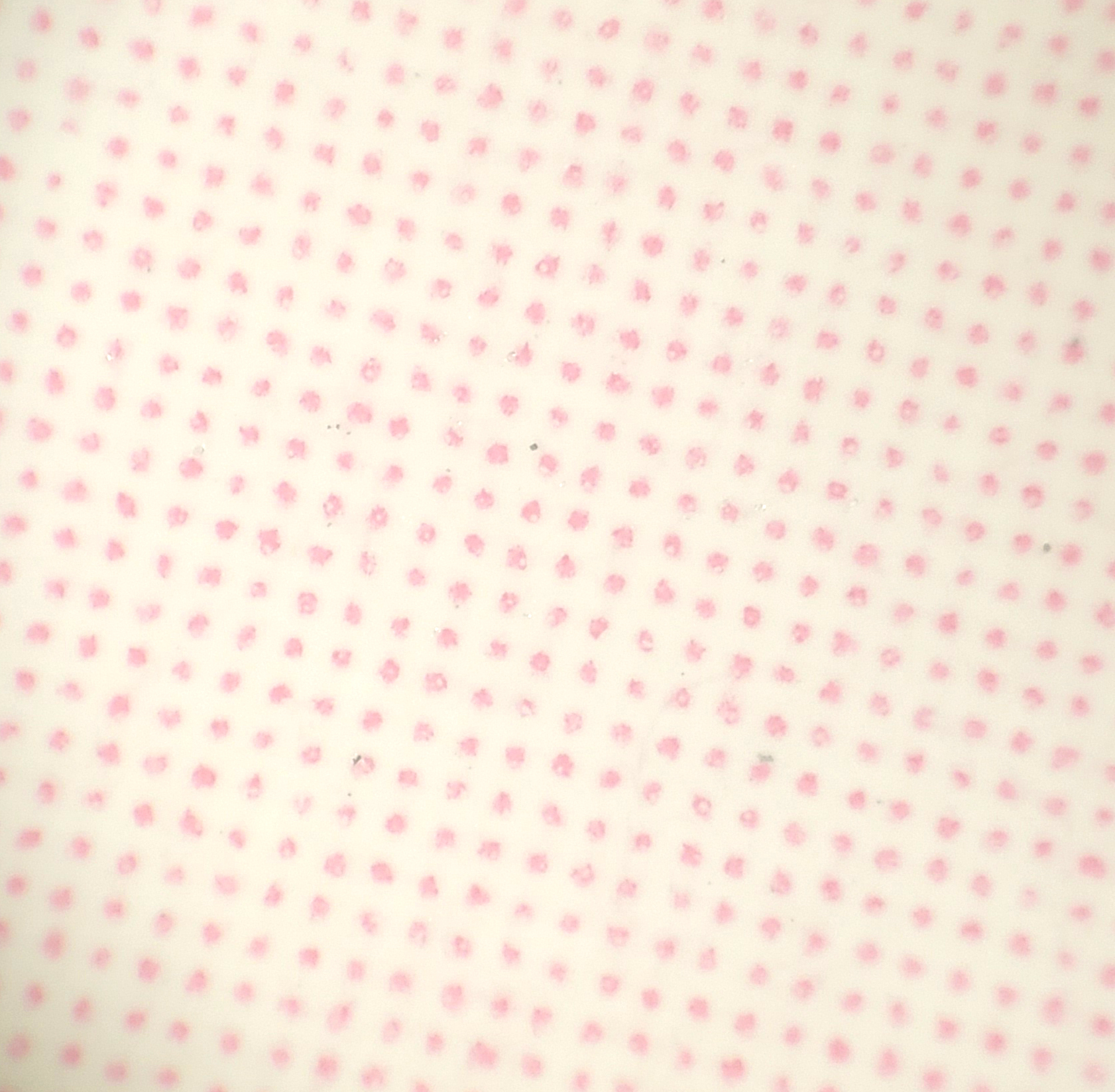

The first image is TopKote and is the new paper. The 2nd image is Endurance and is the previous stock, of which we still have a limited number of sheets.

We printed on these sequentially (i.e. every other sheet).

Neither looks great (contaminated solution at this point?) but you can see an immediate improvement on the Endurance.

We also run other stocks that currently look ok.

Monthly we do calcium rinses and Febo on the rollers.

This doesn't help with the new paper, but cleans up the other stocks a bit.

My take:

The TopKote has excessive calcium or whatever makes it more alkaline than the Endurance. (I have not tested the pH, however, just a guess.)

Any ideas of how to make this work?

New fountain solution? Anything?

We are currently committed to approximately 3-6 months of the paper stock.

The new paper does not print well as well as the previous paper. We get what I call "Splody-dots".

Unfortunately, it took awhile before we noticed this when we printed some very light screens and was extremely difficult to control the results. We ultimately decided to sharpen the curves in the hi-lites to get the results for which we were calibrated.

See attached jpegs.

The first image is TopKote and is the new paper. The 2nd image is Endurance and is the previous stock, of which we still have a limited number of sheets.

We printed on these sequentially (i.e. every other sheet).

Neither looks great (contaminated solution at this point?) but you can see an immediate improvement on the Endurance.

We also run other stocks that currently look ok.

Monthly we do calcium rinses and Febo on the rollers.

This doesn't help with the new paper, but cleans up the other stocks a bit.

My take:

The TopKote has excessive calcium or whatever makes it more alkaline than the Endurance. (I have not tested the pH, however, just a guess.)

Any ideas of how to make this work?

New fountain solution? Anything?

We are currently committed to approximately 3-6 months of the paper stock.

Last edited: