You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

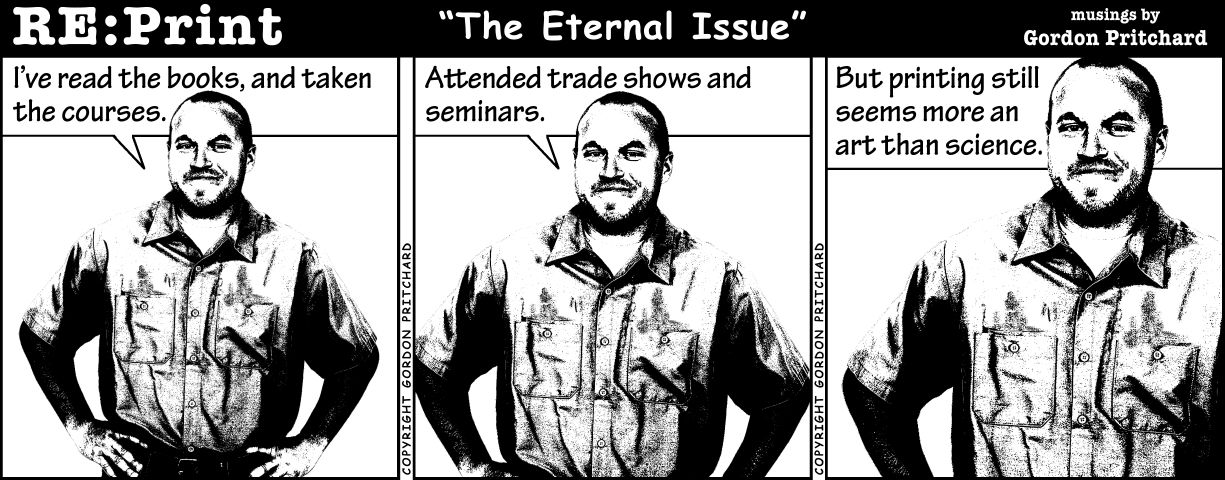

The Eternal Issue

- Thread starter gordo

- Start date

bwaikel

Member

An art?...oh yeah. A good prepress operator is like a surgeon. Surgically correcting shitty files that come from people who make way more than they do. It's been 6+ years since I've been in prepress, so perhaps there's now RIP software that automatically creates bleed where there was once none, sets black to overprint where needed, makes rich black where needed, etc. Basically all of the things pressmen hate the prepress tech for.

Last edited:

"...I never go by numbers . I trust my keen eyes, my artistic instincts and my vast experience..."

Edit: Ok, it's humour...

But let me answer as if your post was for real!

Going by numbers, with at least generic color profiles adapted to the paper and densitometers is the first step to colour management.

Then, using all the modern digital means (closed loop with calibrated screen, RVB chain, press characterization, colour profiles adapted to the press and the paper, etc.) is the way to save time, paper and ink, while getting good predictability with good color consistency and repeatability.

It's the real modern working process, and the complete opposite of:

- human "keen eyes" that are not keen at all... pressmen are not Superman, their eyes are like any other human eyes, subject to huge mistakes, depending mainly of the lighting conditions and the time of the day, and because the colour perception of the human eyes changes with stress, fatigue, and many other parameters depending of physical/mental condition. Also, "keen eyes", as all human eyes, get used to what they see : so they don't see a slow variation in the colours as long as the sheets are coming out of the press and the inks settings drift, making the last printed sheets different of the first.

(I remember a rep of a graphic-art supplies companie who told me that he didn't succeed to sell densitometers to printers, because the pressmen did consider that the use of a densitometer would be an insult to their skills and to their "keen eyes"... but often what they printed was crap, with colours out of reality and drifting... and, of course they, strongly believe and say loud that it was not their fault, it was the pre-press's fault!)

- "artistic instincts" that is not the one of the client, and what is good looking for the pressman may be ugly for the client, and vice-versa

- "vast experience" that is (probably) like any other vast experience of any other people claiming that they perfectly know their job only because they have a vast experience : MY experience of human behaviour in a work environment (not limited to print-shops, but also to some other jobs where, like printing, some theorical knowledge is essential to avoid all the common mistakes) shows me that a "vast experience" without the basic theorical knowledge is often a vast and endless repetition of the same old mistakes.

Bottom line, this the perfect example of the printers of the last century, those who are stuck in 1950, who never did evolve, never will evolve, and (more serious) do teach young people their old myths, urban legends and wrong practices, making them stay at their low level, in a low printing knowledge that seems to be good when limited only to simple jobs and low end customers.

And when Erik Nikkanen says: "It does not have to be an eternal issue but it probably will still be one for a very long time." it is mostly because of people who refuse to evolve to modern color management technics, mostly by laziness and lack of intelligence and knowledge...

... but also because they are feared not to be able to understand this new technics, which will probably make them change from their actual "highly-experienced-worker-with-keen-eyes" state (with high salary) to the "obsolete-out-of-date-overwhhelmed-dinosaure" condition (with a ticket for the unemployment office).

And when a young guy, just coming out of the school with all the modern knowledge of modern printing methods and modern color management comes to their printshop and tries to work as he has learned, guys like that immediately silence him to avoid becoming obsolete-out-of-date-overwhhelmed-dinosaure and force him to work like them, with 1950's technics and knowledge... and the eternal issue goes on for some more time...

Last edited:

Seems you missed my "Tongue-in-cheek"...

Sorry, you're right, I completely missed your tongue-in-cheek...

(perhaps should you have add a "Tongue-in-cheek" smiley?

I have to add in my defence that I have heard so many people saying the same crap very seriously and strongly believing they are the best pressmen in the world, that I didn't see your humour

Last edited:

Alois Senefelder

Well-known member

To Messrs claude and Repro _ Pro and fellow Lithographers,

Being a "Relic from the Stone Age" ..... a great many of the Pre Press Brigade come out with "CRAP" all they have read is the ADOBE Photo - Shop manual, showing an ignorance of

Photo Litho Reproduction in all its facets.

Regards, Alois

Being a "Relic from the Stone Age" ..... a great many of the Pre Press Brigade come out with "CRAP" all they have read is the ADOBE Photo - Shop manual, showing an ignorance of

Photo Litho Reproduction in all its facets.

Regards, Alois

Similar threads

- Replies

- 2

- Views

- 979

- Replies

- 1

- Views

- 160

PressWise

|

A 30-day Fix for Managed Chaos

As any print professional knows, printing can be managed chaos. Software that solves multiple problems and provides measurable and monetizable value has a direct impact on the bottom-line. “We reduced order entry costs by about 40%.” Significant savings in a shop that turns about 500 jobs a month. Learn how……. |