NorwoodPress

Well-known member

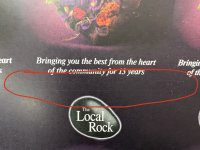

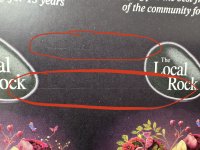

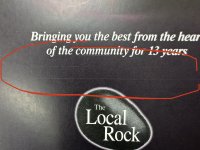

So I was printing some business cards on 350gsm Silk and I stopped the job when I noticed I was getting thin scratch lines all over the sheet.

I called an engineer out and he was adamant that it was the rollers in the booklet maker finisher section.

So he cleaned the rollers and still got the same issue. Then he cleaned the rollers in the decurler module and on the print engine itself, plus the high capacity trays.

He doesn't reckon its not the 2nd BTR as he says thats in good condition, as the meter reading is only on 20,000 clicks.

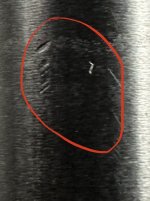

Personally I don't think its from the rollers because they are a certain thickness and these lines are all over the place, some are narrow and some are wide, as you will see from the photos below.

Plus some lines are continuous and others are like a dashed line. Like as though a vinyl record needle is going up and down on the paper scratching it.

The only other thing I can think is if it could be coming off from the IBT belt?

I have tried on different weights / stocks and still getting the same issue.

Any ideas what could be causing it?

I called an engineer out and he was adamant that it was the rollers in the booklet maker finisher section.

So he cleaned the rollers and still got the same issue. Then he cleaned the rollers in the decurler module and on the print engine itself, plus the high capacity trays.

He doesn't reckon its not the 2nd BTR as he says thats in good condition, as the meter reading is only on 20,000 clicks.

Personally I don't think its from the rollers because they are a certain thickness and these lines are all over the place, some are narrow and some are wide, as you will see from the photos below.

Plus some lines are continuous and others are like a dashed line. Like as though a vinyl record needle is going up and down on the paper scratching it.

The only other thing I can think is if it could be coming off from the IBT belt?

I have tried on different weights / stocks and still getting the same issue.

Any ideas what could be causing it?