You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XEROX VERSANT V180 TONER ADHESION PROBLEM

- Thread starter Xose1976

- Start date

SteveSuffRIT

Well-known member

I'm an offset guy so can't help.

In sheetfed offset lithography, I would call this "picking" where ink tack on blanket is stronger than paper, it physically is pulled apart.

In heatset web offset litho, I would call this "blistering" where moisture inside paper gets boiled and vaporized, bursting the paper (like popcorn).

In digital, it's poor toner adhesion to paper (melted toner powder from fuser heat).

Out of curiosity, is it always in the same location, same color build (%TIC/TAC)?

Does it change if you rotate/spin the sheet around or flip/flop the sheet over (other side)?

You say it occurs with all papers, true for different weight/caliper and finish (gloss, matte, plain)?

In sheetfed offset lithography, I would call this "picking" where ink tack on blanket is stronger than paper, it physically is pulled apart.

In heatset web offset litho, I would call this "blistering" where moisture inside paper gets boiled and vaporized, bursting the paper (like popcorn).

In digital, it's poor toner adhesion to paper (melted toner powder from fuser heat).

Out of curiosity, is it always in the same location, same color build (%TIC/TAC)?

Does it change if you rotate/spin the sheet around or flip/flop the sheet over (other side)?

You say it occurs with all papers, true for different weight/caliper and finish (gloss, matte, plain)?

Xose1976

Member

I'm offset business too , but complementary Digital printing too (sorry for my english) I know poor adhesion and fuser is new...I'm an offset guy so can't help.

In sheetfed offset lithography, I would call this "picking" where ink tack on blanket is stronger than paper, it physically is pulled apart.

In heatset web offset litho, I would call this "blistering" where moisture inside paper gets boiled and vaporized, bursting the paper (like popcorn).

In digital, it's poor toner adhesion to paper (melted toner powder from fuser heat).

Out of curiosity, is it always in the same location, same color build (%TIC/TAC)?

Does it change if you rotate/spin the sheet around or flip/flop the sheet over (other side)?

You say it occurs with all papers, true for different weight/caliper and finish (gloss, matte, plain)?

Occurs on coated and uncoated

SoggyWinter

Well-known member

There isn't enough roller pressure or the fuser needs replacement. Double check that the paper profile weight and coating matches the package specifications. If it does not, fix it, run 'clean toner' sheets one color at a time, and try again. If that does not work, get a new fuser.

Xose1976

Member

Hi. Yes, originals, I have an official xerox maintenance contract, they bring the supplies. The fuser is new. Defective?are you using all original parts and supplies?

thats a fuser issue

Xose1976

Member

The type of paper was tested. I also did the toner and fuser cleaning, in the maintenance section of the tools tab.There isn't enough roller pressure or the fuser needs replacement. Double check that the paper profile weight and coating matches the package specifications. If it does not, fix it, run 'clean toner' sheets one color at a time, and try again. If that does not work, get a new fuser.

Could the supposed new fuser be faulty?

It was perfectly sealed and packed. And a Xerox technician brought it in.

Xose1976

Member

Sorry, don't understand your replyPanic stop the machine to see where the defect occurs.

Looks like maybe the toner density has gotten too high. When you do the routine for Uniform Density choose set for to factory default. I have seen this happen on the 2100 and 3100 where somehow the toner density gets too high if one does not set it back to factory default before doing the Uniform Density.

Xose1976

Member

What he says about the paper I usually apply it to some supports, but it is not the case. It is a material that has been perfect for two years. Thank you!Is the temperature of the fuser right, you can try upping the settings, not sure what you can do with that machine. We always use to cheat and tell the machine it was printing on a thicker stock. Check your settings, is the paper rated for digital?

Xose1976

Member

I have managed to speak to a technician and he comments that he sees the problem in the mixture of toner and developer. Too much toner, if the mixture is not perfect those problems happen. What he does not understand is how it has become misaligned like that. They will finally come to see it, but he says it is going that way. In a way it IS a toner density problem. More like excess toner.Looks like maybe the toner density has gotten too high. When you do the routine for Uniform Density choose set for to factory default. I have seen this happen on the 2100 and 3100 where somehow the toner density gets too high if one does not set it back to factory default before doing the Uniform Density.

The problem I think is if you run Uniform Density on top of Previous UD Setting without going back to the Factory Default some how it creates to much Density. Thats what I saw with the 2100 and 3100 printers.I have managed to speak to a technician and he comments that he sees the problem in the mixture of toner and developer. Too much toner, if the mixture is not perfect those problems happen. What he does not understand is how it has become misaligned like that. They will finally come to see it, but he says it is going that way. In a way it IS a toner density problem. More like excess toner.

Just run your Uniform Density and set it back to factory default. You should not need a tech for that.

Xose1976

Member

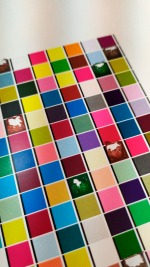

PROBLEM SOLVED. Excess toner. The technician made me go to the maintenance and diagnostics menu (under technical mode), then to diagnostics. In that menu he has made me scroll to PROCON. There are three options. By pressing Procon ON, the machine makes some adjustments and prints a test. After doing a toner cleaning and running that test, the problem has been solved. As you say, that generated an excess of density, the machine believed that it was missing and took more toner. Look at the photo.The problem I think is if you run Uniform Density on top of Previous UD Setting without going back to the Factory Default some how it creates to much Density. Thats what I saw with the 2100 and 3100 printers.

Just run your Uniform Density and set it back to factory default. You should not need a tech for that.

There was no gradient, excess toner. Using that test PROCON has returned to normal.

Thanks a lot !

Attachments

Similar threads

- Replies

- 5

- Views

- 651

- Replies

- 6

- Views

- 640

- Replies

- 8

- Views

- 1607

InSoft Automation

|

InSoft Automation Unveils Imp Version 14

Revolutionizing Layout Planning and Automation InSoft Automation announces the launch of Imp Version 14, the latest iteration of its industry-leading cost-based layout planning software. Packed with cutting-edge features, this release redefines efficiency, automation, and workflow optimization for printing and finishing processes. Learn more……. |