streetsnake

Active member

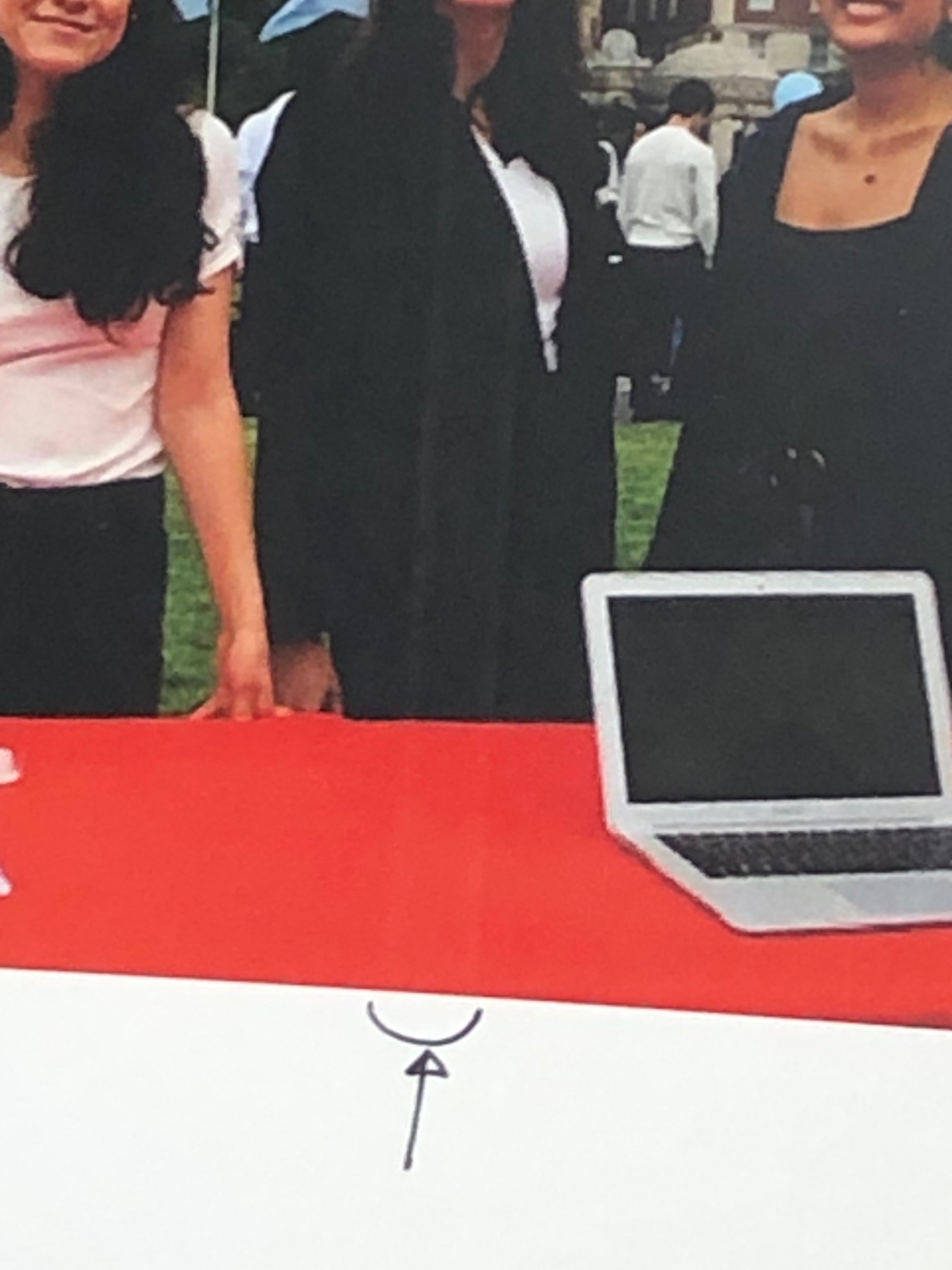

With the help of everyone figuring out how to tackle the calibration issue, I've run into another issue on the Xerox C70. I was trying to do some test runs with 80C and 100C and ran into this issue. Can anyone help me diagnosis were it seems to be coming from. I'm guessing one of the rollers but I'm not entirely sure, nor how to tackle the problem. I've tried tried various settings but nothing has fixed the issue.