PricelineNegotiator

Well-known member

Digimc, do you have a C75 or J75? Just checked and did not find anything. I don't remember it being an add-on for the machine.

I have a J75 with the two drawer high capacity feeder, I only have this machine for 10 months. When loading stock into drawer 6 the

UI allows me to select "envelope". It's only after seeing the online video for printing envelopes on the V80 that I decided to get down on my hands and knees and have a look

Digimc, do you have a C75 or J75? Just checked and did not find anything. I don't remember it being an add-on for the machine.

I have a C75 and the attachment but wehn I try to run #10 they come out wrinkled. Is there some kind of other trick or setting I should be using?

I have a C75 and the attachment but wehn I try to run #10 they come out wrinkled. Is there some kind of other trick or setting I should be using?

I've been looking at a V80 for doing envelopes, however after demoing two units at different sales offices, they tried a 3rd location and still have an issue with skewing, pretty badly. They sent some to Rochester and got them to work (although they could not when I was there because the engine and Fiery were not talking, and it crashed on the 2100 immediately and they couldn't get the box back up). Interestingly enough, they could not get closer than 3/16" on those three machines but did get 1/8" on the 4th go around I was not there for... doesn't instill confidence with me at all.... any others have these issues?

We run envelopes all the time on our V2100. A2's all the way up to 10 x 13. Window & Non-Window. We probably run, on average, around 10,000 per month. They run smooth as silk and registration is dead on. If I had a gripe, it would only be that I wished there some other output option besides the upper output tray. At the speed and smoothness of the run, that upper tray gets full every couple of minutes, so, basically, an operator has be standing there constantly pulling stacks of the printed envelopes from the output tray and placing them back in the envelope box. Sure would be nice if they could be output to one of the bottom trays or a stacker............

They didn't even have mine at one location, and Xerox tried their own... don't think it is the envelopes.Are you sure it is the machine and not the envelopes themselves? Had a bad batch of envelopes, tried a new box and everything was straight again.

Yeah, that is one situation I am trying to avoid, having my operators babysit. That part stinks.We run envelopes all the time on our V2100. A2's all the way up to 10 x 13. Window & Non-Window. We probably run, on average, around 10,000 per month. They run smooth as silk and registration is dead on. If I had a gripe, it would only be that I wished there some other output option besides the upper output tray. At the speed and smoothness of the run, that upper tray gets full every couple of minutes, so, basically, an operator has be standing there constantly pulling stacks of the printed envelopes from the output tray and placing them back in the envelope box. Sure would be nice if they could be output to one of the bottom trays or a stacker............

Yeah, that is one situation I am trying to avoid, having my operators babysit. That part stinks.

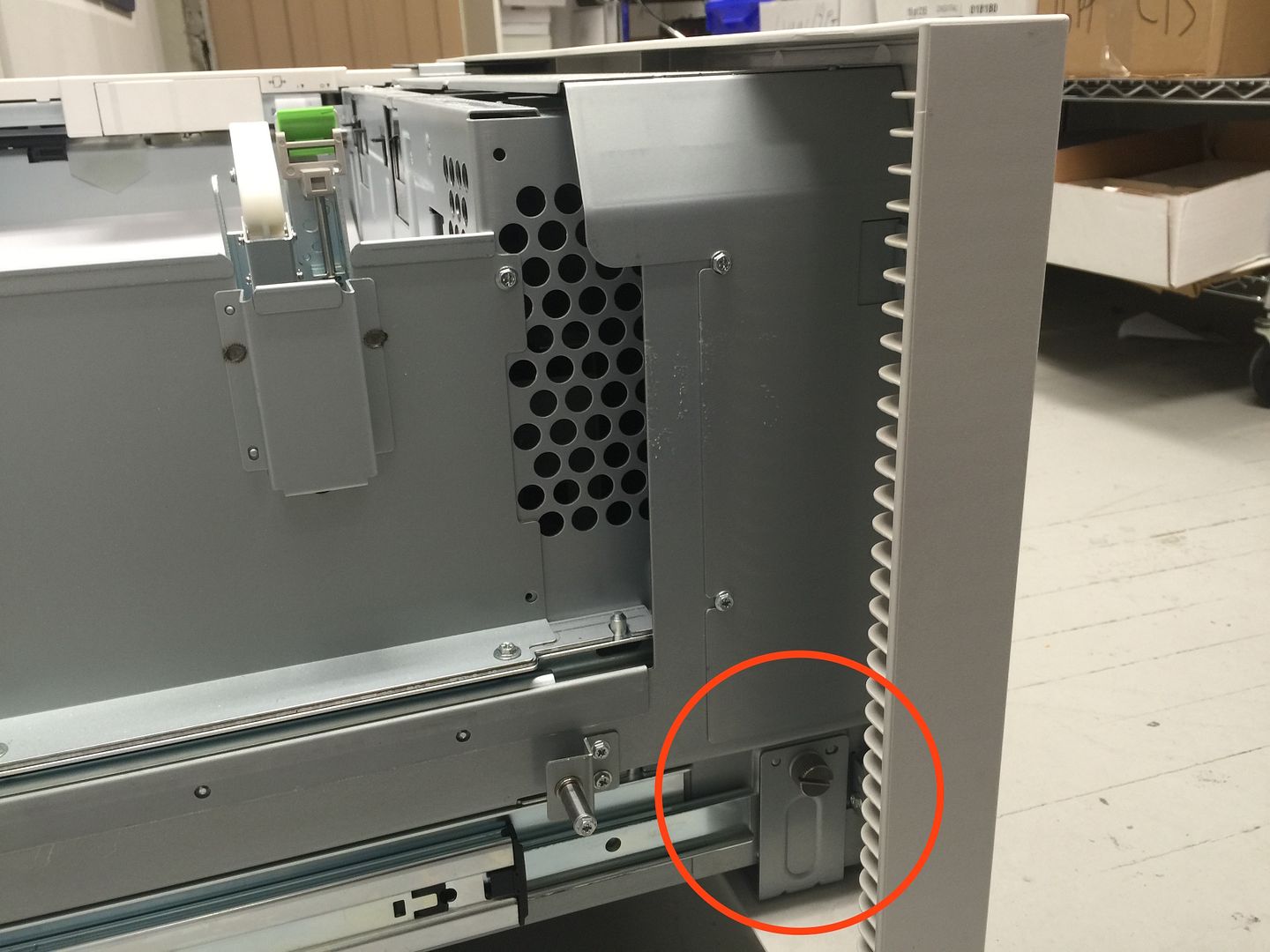

We print a lot of envelopes on the Versant 80, it comes with the handy envelope feed screwed into the bottom of Tray 6 (your large capacity tray) which lets you do DL size in bulk, before that we were running them from Tray 5 and feeding them by hand, which took too long. Until the tech unscrewed the envelope feed plate and showed us the light. . . no issues what so ever. .

|

InSoft Automation Unveils Imp Version 14

Revolutionizing Layout Planning and Automation InSoft Automation announces the launch of Imp Version 14, the latest iteration of its industry-leading cost-based layout planning software. Packed with cutting-edge features, this release redefines efficiency, automation, and workflow optimization for printing and finishing processes. Learn more……. |