Pressmanscooter

Well-known member

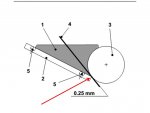

I run a '92 40" Heidelberg CD and I have 1 unit that leaks ink between the fountain roller and end plates. Its been going on for over a year. Tried everything.... New end plates, new plastic over the metering cylinders, new foam piece for under the end plate. Nothing works. All good advice welcome.

Thanks

Scott

Thanks

Scott