You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

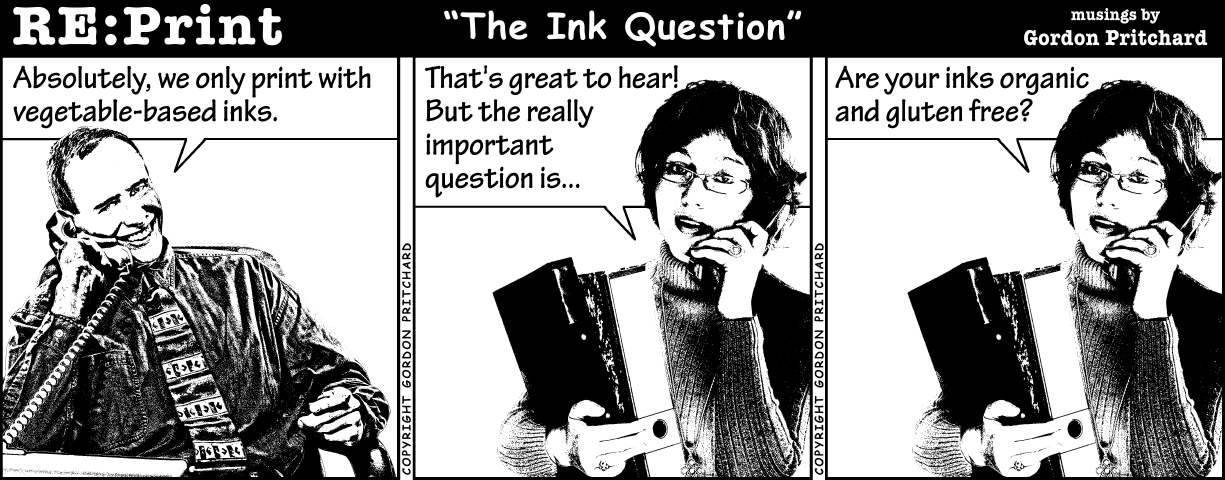

The Ink Question

- Thread starter gordo

- Start date

Alois Senefelder

Well-known member

cementary,

A stupid reply and in "Poor Taste"

Regards, Alois

A stupid reply and in "Poor Taste"

Regards, Alois

keith1

Well-known member

I recall when lead & other nasty things were starting to be removed from inks. It was hard to know from one batch to the next what you were getting. Lots of experimenting by the ink companies. But generally as inks and chemistry were becoming less of a health hazard, we had to mix in our own additives to get these inks to run properly. This kind of defeated the purpose, but I recall using more gums, varnishes & dryers, trying many different water mixtures.

It was trying at times. I guess it had to start somewhere and it all worked out to everyone's benefit over the long run.

Same goes for recycled paper. At first many of the fibers were so loose. It was a pain to print on. But eventually they got it all sorted out and we're better off for it.

Washes were up a league or 2. Full of cool stuff like acetone. Thankfully that changed and probably saved countless lives. I had a boss that brought in a 45 gallon drum of MEK. Methyl Ethyl Ketone, he wanted us to use in place of blanket wash. He claimed it was cheaper (it wasn't). We refused to use it except to soak a cotton pad to use as blanket fix. One day Workers Comp. came in and that was the end of that experiment.

It was trying at times. I guess it had to start somewhere and it all worked out to everyone's benefit over the long run.

Same goes for recycled paper. At first many of the fibers were so loose. It was a pain to print on. But eventually they got it all sorted out and we're better off for it.

Washes were up a league or 2. Full of cool stuff like acetone. Thankfully that changed and probably saved countless lives. I had a boss that brought in a 45 gallon drum of MEK. Methyl Ethyl Ketone, he wanted us to use in place of blanket wash. He claimed it was cheaper (it wasn't). We refused to use it except to soak a cotton pad to use as blanket fix. One day Workers Comp. came in and that was the end of that experiment.

Similar threads

- Replies

- 2

- Views

- 203

- Replies

- 14

- Views

- 547

- Replies

- 11

- Views

- 1718

PressWise

|

A 30-day Fix for Managed Chaos

As any print professional knows, printing can be managed chaos. Software that solves multiple problems and provides measurable and monetizable value has a direct impact on the bottom-line. “We reduced order entry costs by about 40%.” Significant savings in a shop that turns about 500 jobs a month. Learn how……. |