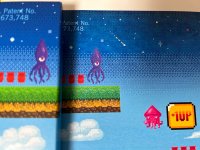

We've just replaced the 2nd BTR and coated stock at 271 GSM prints just fine but when I try and run heavier 300+ coated cover I'm getting splotchy uneven areas of color. I've checked drum carts, calibrated the color density etc. At this point I'm thinking this may have to do with humidity but I'm not sure what types of visual flaws can be created by humidity? See attachment. Image on the left is a box printed last year, image on right is a print from today. Again, other jobs are printing just fine, it seems to have to do with the thickness of the paper. I've printed the same image on the heavier paper and thinner paper and get different results.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Versant 280 Splotchy/Mottled Color on Heavy Stock

- Thread starter VanCleef

- Start date

sidneykidney

Well-known member

I use a V80 so I'm not sure what the equivalent setting is on the V280 but change the paper type setting to Embossed or Cast Coated at the heaviest paper weight.

I wanted to follow up on this thread. After a week or so of not using the printer upon returning to printing the issue was gone. I believe the splotchy color was happening due to static electricity perhaps caused by quick fluctuations of hot and cold in the workplace. We were experiencing extreme cold temps at the time.

That's all I've got! The machine seems to be printing fine now. Thanks for the feedback.

That's all I've got! The machine seems to be printing fine now. Thanks for the feedback.

sidneykidney

Well-known member

I used to have a similar problem at our previous location.I wanted to follow up on this thread. After a week or so of not using the printer upon returning to printing the issue was gone. I believe the splotchy color was happening due to static electricity perhaps caused by quick fluctuations of hot and cold in the workplace. We were experiencing extreme cold temps at the time.

That's all I've got! The machine seems to be printing fine now. Thanks for the feedback.

Next time this happens, try this little test which I used to use:

Heat up the sheet by printing a tiny black dot on the page (outside of the print area) and then put the same sheet through again but this time with your CMYK image.

I used to do this when running 350gsm Business Cards which used to mottle on the solids due to the cold.

narseman

Well-known member

I do have this problem. Will try your trick. Thanks.I used to have a similar problem at our previous location.

Next time this happens, try this little test which I used to use:

Heat up the sheet by printing a tiny black dot on the page (outside of the print area) and then put the same sheet through again but this time with your CMYK image.

I used to do this when running 350gsm Business Cards which used to mottle on the solids due to the cold.

Similar threads

- Replies

- 7

- Views

- 1802

- Replies

- 6

- Views

- 637

InSoft Automation

|

InSoft Automation Unveils Imp Version 14

Revolutionizing Layout Planning and Automation InSoft Automation announces the launch of Imp Version 14, the latest iteration of its industry-leading cost-based layout planning software. Packed with cutting-edge features, this release redefines efficiency, automation, and workflow optimization for printing and finishing processes. Learn more……. |