hello there!

I do no not work with printing per se. I'm a biologist in my master's and part of my research involves printing butterfly wings.

Mind that my research is not the printing itself, but what I'll do when I'm done with the printing: I've 'read' butterflies' wings in a spectrophotometer, have a profile (a mean curve if you will) to use as a pattern and have printed wings that will, later, be read as were those real wings. We're creating fake butterflies so we can use them in our experiment (the strangest that it may sound, it's a vastly used method)

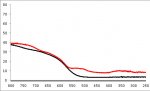

the thing is, I've have already taken all the measures and have a few discrepancies in my curves (my 'real' profile and my 'fake' profile. (so to have a better grasp: my curves are in nm, my 'fake butterflies' curves are slightly more reflective than they should from 550nm to 250nm. I'd want the curve to have a slightly more abrupt descent at around 550nm than it does). What could it be the problem I'm facing? Is there a way to feed a image edition program a nm curve and have it printed? Now I'm using Photoshop. Should I be using Corel Draw? Am I absolutely wrong? Any answer is welcome.

My best regards

I do no not work with printing per se. I'm a biologist in my master's and part of my research involves printing butterfly wings.

Mind that my research is not the printing itself, but what I'll do when I'm done with the printing: I've 'read' butterflies' wings in a spectrophotometer, have a profile (a mean curve if you will) to use as a pattern and have printed wings that will, later, be read as were those real wings. We're creating fake butterflies so we can use them in our experiment (the strangest that it may sound, it's a vastly used method)

the thing is, I've have already taken all the measures and have a few discrepancies in my curves (my 'real' profile and my 'fake' profile. (so to have a better grasp: my curves are in nm, my 'fake butterflies' curves are slightly more reflective than they should from 550nm to 250nm. I'd want the curve to have a slightly more abrupt descent at around 550nm than it does). What could it be the problem I'm facing? Is there a way to feed a image edition program a nm curve and have it printed? Now I'm using Photoshop. Should I be using Corel Draw? Am I absolutely wrong? Any answer is welcome.

My best regards